Last month, Sergio Hamernik, head honcho at Mercury Magnetics, walked us through the intricate process of rewinding a vintage transformer. This month, we dig a little further into the details of winding, materials, the ways age affects some transformers, and why some of them fail.

When you rewind a transformer, do you use the same wire used in the 1950s and ’60s?

No. We use high-purity, oxygen-free copper magnet wire made in the U.S.A., and we use it because of its tonal properties – it’s sonically superior and more consistent than the wire used in the ’50 and ’60s. Wire, back then, had about half the temperature and electrical performance capability of Mercury’s standards.

We, as players, would prefer to use wire from the ’50s and ’60s compared to offshore and south-of-the-border wire. We tried them, thinking we’d save our customers some dough, but test results yielded dull tone and we saw inconsistent batches with too many instances of insulation breakdown. The stuff was not even up to the standards of vintage wire. Further, in real-life tests putting amps through their paces, the sonic differences were noticable to the guitar players here at Mercury, and those working for the recording studios here in Southern California.

Have you ever seen a negative effect of age on a transformer?

In some cases, yes. Sometimes, your ears pick up on the effects of aging before you realize what’s happening – they produce dark, dull, and fuzzy tones with a general sense of lower output volume.

If anything in a transformer suffers from aging, it will most likely be the core. Two major contributors cause a negative effect of aging and affect your tone. Before World War II, the science of processing iron was not up to snuff. It was difficult to boil out residual carbon, and even a miniscule amount of carbon in older iron causes it to age. As an iron core ages, its magnetic conductivity begins to poop out, slowing the transformer’s responsiveness with increasing losses. The result is less output with only lower mids breaking through.

During WWII, the war effort created a shortage of iron. So, many transformer companies made cores from sheet metal, like that used to make soup cans! These had the wrong kind of iron and harbored plenty of carbon, to boot – do not confuse iron with steel! Finally, when silicon was implemented to help force the carbon out of post-war iron, transformer iron became stable enough to outlast us all.

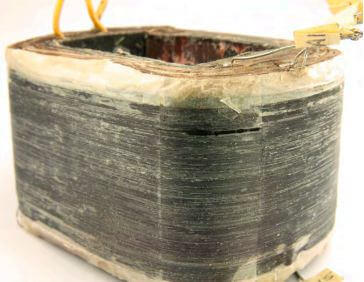

Another contributor to transformer aging comes from humidity. Amp owners who live in humid climates have noticed their tone changes over the years, especially if their older amps had transformers built around paper bobbins, which have always run the risk of moisture absorption affecting tone. Conversely, we found that transformers with plastic bobbins weren’t likely to suffer tone degradation via moisture saturation. A couple excellent examples are the original Partridge and Radiospares transformers from England – with the fog and rain they experience, these transformers held up quite well. That may explain why coating paper in wax was attempted early on, and to verify that humidity affected output transformer tone, we flew in transformers from amps made in the ’60s that had never left the U.K., all with paper bobbins, and put through a dehumidifying process, then re-sealed them in varnish and gave them a full bake. The owners freaked out and thanked us for giving them their original tone back! One called to thank us personally when he realized it was his tone fading over the years, and not his ears! He said that as time passed, he noticed less treble and a lot less note separation and definition. Others had this mastaken belief that their amps were getting too old to play.

Obviously, the rewound transformer for the 1960 Vox AC15 we’ve been working on the last few installments won’t be dipped in wax. What will you use to insulate it?

It’ll receive a fresh dip of varnish.

What can we expect the differences to be between the rewound transformer and the original?

It should sound as good as when it left the showroom in 1960. The only other option, as far as upgrading the tone, would be to try one of our ToneClones, which are copies of the finest celebrity-owned and played “pick of the litter” transformers. It’s likely you’ve heard these transformers in action on your favorite recordings.

Has a rewound transformer come back to you shortly after it was sent out?

Yes. Installer error happens, and if you don’t find and fix the problem that caused the transformer to blow in the first place, you’re setting yourself up for a repeat performance.

Another thing that’s fairly common is the use of N.O.S. tubes, usually bought from an online auction. We had a customer who, after installing his rebuilt output transformer, decided to re-tube his amp with 40-year-old American-made originals. As luck would have it, one of the tubes shorted and caused a different failure in the newly rebuilt transformer.

Is every old transformer destined for a rewind, or could some go on forever?

Not every old transformer will need to be rewound, if taken care of poperly. Most may outlast the “Iron Age” of guitar transformers, which we’re living in now. The push for solidstate technology is tenacious enough to replace tube-/transformer-based amps in the long term. Tubes may go, but they’ll have to pry the transformers from my cold dead fingers before I’ll give them up!

We recently put transformers of all kinds – old and new – to the test by volunteering to help flood victims in Nashville. We offered to test and restore water-damaged transformers, and encountered some pretty nasty stuff. Yet, less than five percent of them needed to be rewound – namely, those with paper bobbin insulation or amps that had been turned on before the transformers were tested. Some transformers were from amps that had been submerged in sewage for weeks! The odor was so foul we had to air them out, and the staff actually had to draw straws to determine who was going to work on them.

You must have your share of unpleasant jobs….

Man, you got that right! But there’s nothing like the fresh smell of varnish in the morning to help one deal with that challenge. We did manage to extract the moisture and re-seal these transformers with varnish. The sacrifices you have to do to help fellow musicians….